MDL

TECHNICAL DIE-CAST EXPERTS

BENEFITS OF CHOOSING A

PROVEN DIE CAST SUPPLIER

We pay meticulous attention to detail throughout our manufacturing process in order to add the finishing touch. The quality of our high-pressure die casting is also underpinned by state-of-the-art design and development technologies, access to market-leading finishing processes and a customer-driven ethos that you’d expect from a family business with over 80 years experience.

MDL understands what it takes to produce components with an exceptional surface finish.

We also have the technical expertise to produce zinc diecast components that will flawlessly accept powder coating, wet paint coating, chrome plating, copper plating and other finishes. Finally, our attention to detail is unsurpassed and dictates the way in which every product is lovingly hand finished and assembled.

As such, we are able to deliver components that consistently improve the way in which end users interact with our customers products.

OUR DIE CASTING TECHNICAL CAPABILITIES

MDL is a quality assured organisation and accredited to BS EN ISO 9001:2015. Our internal quality control processes have been developed to support the delivery of assured component integrity, repeatability and consistency.

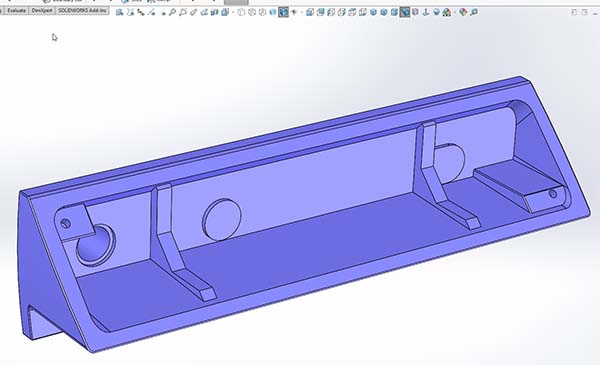

We work with clients to provide unrivalled technical support throughout the design and development process. This approach allows us to either configure brand new components or refine customer designs to make them quicker, easier and more cost-effective to manufacture.

Our capabilities include:

- CAD / CAM capabilities including SolidWorks

- Steinbichler 3D scanning

- Rapid prototyping and Stratasys 3D printing

- Toolmaking and modification

- Core making

- Machining, finishing and assembly

ENQUIRY

Let us know as much as you can about your project, and we’ll get back to you as soon as possible.

Speak to us directly on 0121 520 1177